From the Design Quarterly: Why a buildings engineer may see an earth tube in your future

January 24, 2019

January 24, 2019

Ask an expert: Advancing technology means that buildings engineers are integrated into building design early in the process, which could save money in the long run

Tariq Amlani is a mechanical engineer and member of Stantec’s Global Health leadership team. He specializes in the design and commissioning of mechanical systems—heating, ventilation, AC, plumbing, medical gasses, fire protection, and life safety systems—in healthcare facilities. He sat down with John Dugan, editor of the Stantec Design Quarterly, to talk about how technology and integration are changing the design process.

Tariq: Absolutely. In my opinion, the structural engineer has always been at the front of the pack. The structure has such an influence on the architecture. But the mechanical and electrical systems were often stuffed behind walls or on the roof with no further thought as long as the systems were functioning. We’re seeing that way of thinking disappearing. We’re seeing a higher degree of engagement between the client, architect, and building engineers—really, a more integrated approach to building design.

For example, because of automation, the role of mechanical and electrical engineer now has more influence over design and the occupants’ experience of the building. With automated buildings, you swipe your card in the morning. The elevator automatically opens and you’re swept up to your designated work floor. Your corridor path is illuminated. Your thermostat is pre-set to your preferred temperature. Your task lights are on. The user experience is influenced by the electrical engineering systems, communication systems, security, and information systems.

Clients and architects are recognizing the impact of mechanical systems on the energy consumption of buildings. Smart buildings that provide energy usage information direct to users have been shown to reduce energy consumption. Some studies demonstrate up to 20% savings in this manner. That’s huge.

I’ve seen windows into mechanical rooms, something that we used to hide. These systems are now on display because owners are proud of their buildings and want to educate their occupants about energy consumption. They want to say: “Look at this geothermal system or a heat recovery system.”

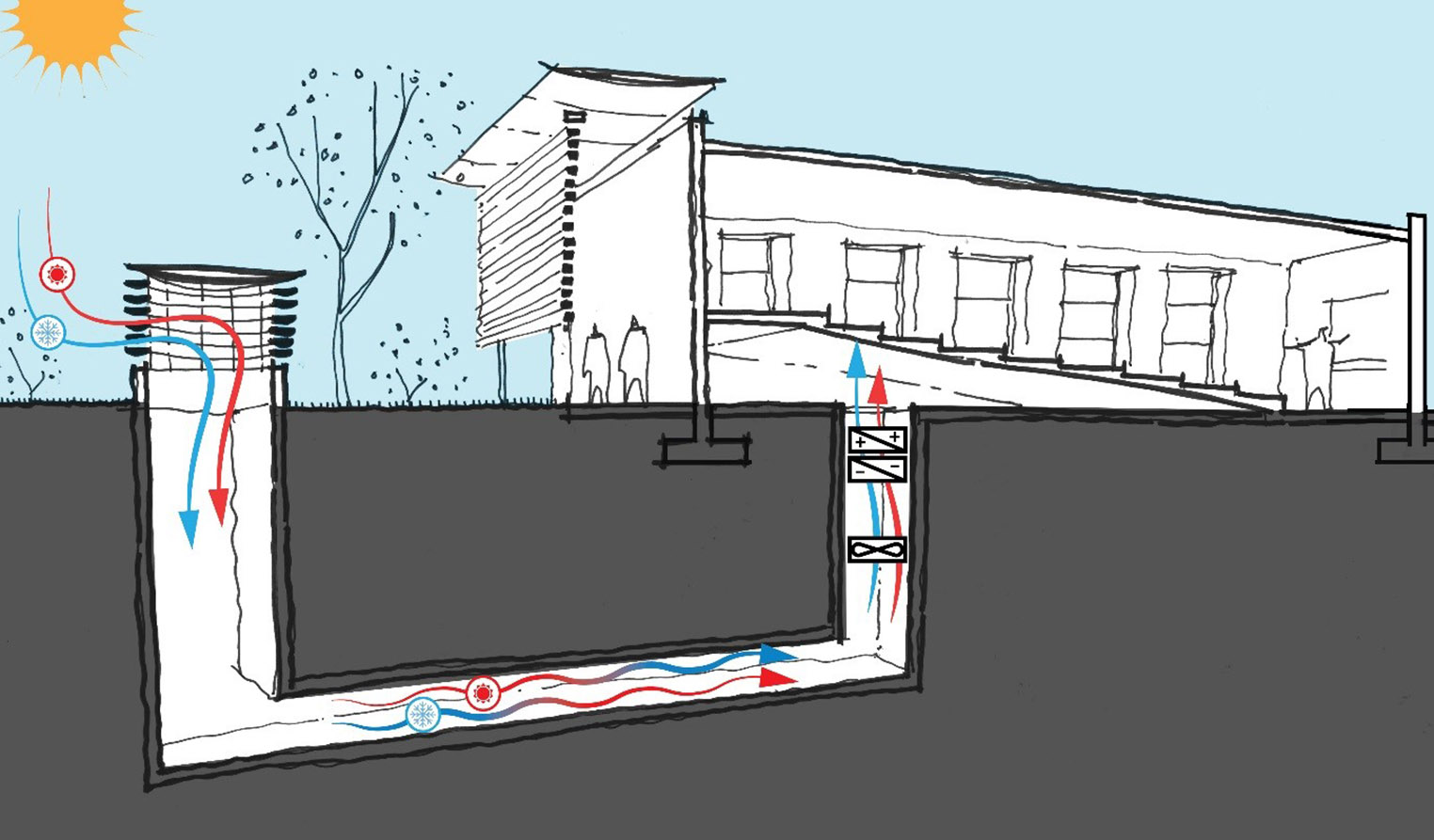

A simple thermal labyrinth. (Illustration by Animish Kudalkar)

Tariq: Totally. We are doing trade schools where the function of the building is to teach students how to design and build buildings, so making these systems transparent, understanding how things connect and operate is a huge contribution to hands-on learning.

Read and download the Design Quarterly Issue 04 | Intersections

Tariq: Efficiency. It’s becoming more broadly understood that it’s efficient to bring designers and engineers together early in the conceptual stage of the project. In modern healthcare projects, for example, engineering construction cost can amount to 50% of the total building cost. If the conceptual design approach is already decided, then we are stuck having to potentially compromise the services or system performance because of the preconceived design, or we have to find creative zoning solutions, we have to engineer a solution to the architecture. That can get very expensive and, from a system performance perspective, can be less than optimal. Alternatively, if we’re at the table early on, we can say, “Hey that’s great direction, but did you realize it’s going to have these additional costs?” Or, “What you’ve drawn there is great, you’re going to have these operable windows, so maybe we can delete some of the cooling systems?”

By having an integrated design approach early on, you can realize some efficiencies. If the cake mold is set before we even get to the kitchen, there’s a lot less we can do to shape the outcome. In general, there’s a trend toward bringing the engineers, architects, owner, and operator together and asking, “What makes the most sense here?” That way you can get more for less.

Tariq: Earth tubes is one. We can use them to preheat or precool the air before we bring it into the building. If we see the building massing, early in the process and there is an area of excavation adjacent to the building. Rather than spend money to refill that excavation with non-native material, we say, “Wait a minute, why don’t we save the money and build an earth tube? I can design my mechanical system so that the air can be drawn through that tube and by doing so we can preheat the air in winter and precool that air in the summer?” It’s a relatively simple solution that leverages the power of mother nature. We did this at Nanaimo Regional General Hospital. Every year, the thermal labyrinth system returns $5,000 to the client in energy savings, based on real measured data. That savings will continue for the life of the building. And that means more money to provide top quality care to patients.

Because of automation, the role of mechanical and electrical engineer now has more influence over design and the occupants’ experience of the building.

Constructing a thermal labyrinth is more justified when a project requires the excavation of material for technical reasons. Rather than spend resources on backfill, a simple thermal labyrinth can be constructed for use as an air pre-conditioner. In winter, the labyrinth or “earth tube” can precondition the outside cold air in the earth, warming it before it is heated for occupied spaces. Inversely, it can take warm summer air and cool it in the earth before it is air-conditioned and blown inside. More sophisticated thermal labyrinths can take the cool night air and hold it for release the next day and the reverse.

Tariq: Yes! I’m really excited to be using Matterport scanning in our work now. Matterport scanning produces a detailed high-definition three-dimensional image of a building interior. Think of Google Street View but applied on the inside a building.

I was blown away by the technology, and by the multitude of applications in design. Originally, we used it to document a hard-to-reach site more accurately for mechanical engineering. Then, all these other possibilities sprouted up. Suddenly, the architects, electrical and structural engineers, everyone can use this 3D space for their own design needs. They are able to determine finishes from it, structural supports, and the routing of high voltage conduits. And that was just the beginning! Now, we’re taking it further, and merging the scan with new mechanical design drawings in Revit to create virtual fly-throughs with the 3D imagery and virtual elements.

Clients are finding all kinds of uses for it. In remote locations, it can solve the problem of getting bidders out to the site, for example. One client used it to create a virtual tour of their new library and museum before it opened. This virtual as-built documentation reduces client cost and gives them more certainty when they’re doing a renovation.

We’re using it to document a hard-to-access linear accelerator vault at the BC Cancer Center. We went in once and scanned the whole department. This way we can virtually revisit the space as needed in design, without disrupting critical, life-saving, clinical operations.

Now we’re talking to owners about doing a Matterport scan during construction before you board up the walls, so they have a 3D as-built digital record of pipe locations, fittings, studs, structure, etc. That is invaluable for future building operation. And, contractors love this tech too, it can be used for prefabrication, speeding up the construction process too. It opens a whole new realm.

Now, it’s a matter of dreaming up what’s next. I like sharing this technology with others. It’s great to see people’s expressions when they see this. They fall off their chairs. Then, you see the wheels start to turn. They start thinking of new ways to use it.

And to me, when your imagination is your only limitation, that’s pretty exciting.